High pressure for the energy of tomorrow

Our high-pressure compressors are the ideal solution for compressing hydrogen. Thanks to the customised design of our systems, we can realise projects that enable both variable intake pressures and extremely high final pressures.

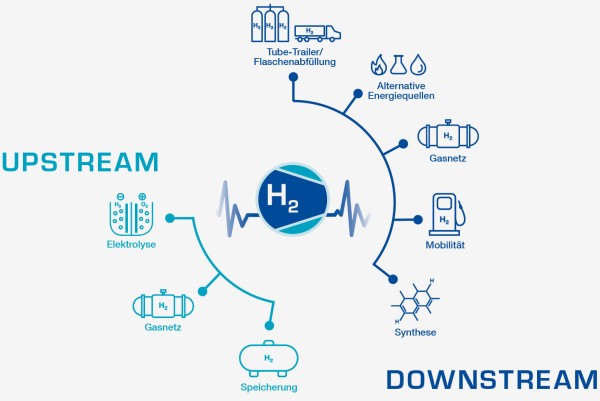

Hydrogen - the future of energy

Hydrogen offers a climate-friendly alternative to fossil fuels - whether for refuelling fuel cell vehicles, as a synthetic fuel, for feeding into the natural gas grid or in steel production. Several compressors play a central role here: after electrolysis, they compress hydrogen to up to 1,000 bar in order to increase the energy density and enable efficient storage - for a green future with lower CO2 emissions.

Your benefit

With our oil-free and wear-free compressors, regeneratively produced hydrogen can be stored efficiently and safely.

Let our heart beat for your hydrogen system

- Maximum availability thanks to high-quality compressors

- Safe storage and supply of hydrogen in the low- and high-pressure range

- Flexible, modular system design for various input sources (on-site generation, electrolysis, tube trailer)

- Energy-optimised control and guaranteed H2 purity to reduce your operating costs

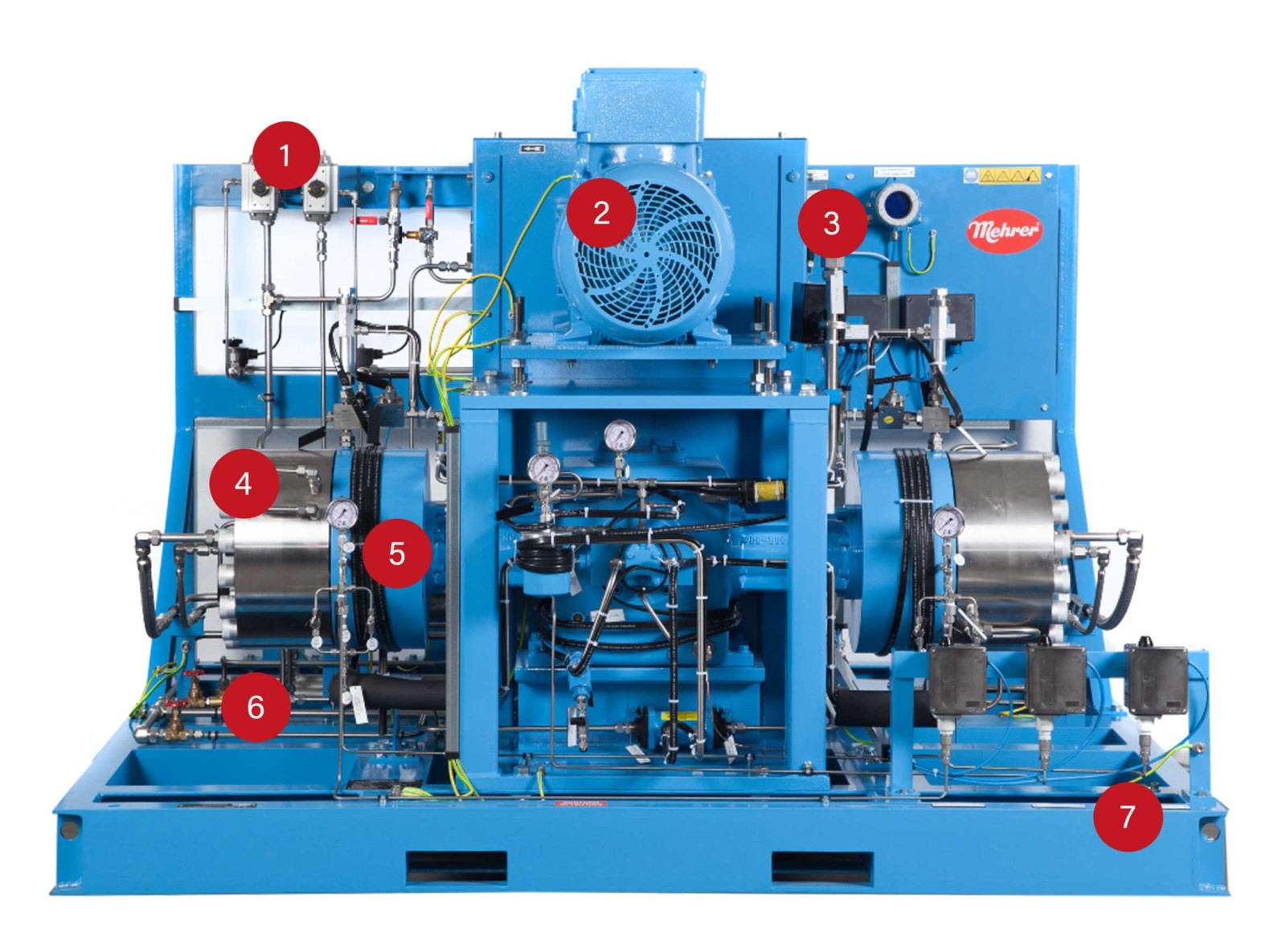

Our hydrogen compressors - ideally designed for new energies

1 | Pneumatic shut-off valves - Safely integrated into hydrogen systems

2 | Drive motor - Designed for frequency converter operation for flexible volume flow control

3 | Signal transmitter - In Ex version for potentially explosive atmospheres

4 | Gas train - Made entirely of stainless steel for maximum durability

5 | Cylinder heads - Made of stainless steel for a long service life

6 | Heat exchanger - Water-cooled stainless steel heat exchanger for efficient recooling

7 | Base frame - Vibration-isolated or permanently mountable

Several compressors in use

Hydrogen

Sunfire GmbH, one of the world's most innovative energy companies, develops solutions for hydrogen production. For compression, Sunfire relies on the powerful compressors from Mehrer Compression GmbH.

Fuel cell

For efficient and fast refuelling of fuel cell vehicles (350 bar for buses, 700 bar for cars), hydrogen is extracted in cascade from buffer storage tanks. Several diaphragm compressors ensure the continuous filling of these storage tanks and are an essential part of the process.

Refueling system

Several diaphragm compressors are the key component between the supplied hydrogen and the refuelling system for fuel cell buses. The pressure difference between the storage tanks and the vehicle tank ensures that the hydrogen flows efficiently.

Compressors as the key to the energy transition

The magazine "Pumps and compressors for the global market 2020", published by the VDMA, presents our dry-running high-pressure compressors for water compression.

Put together the optimum compressor for your process from our modular product portfolio. By combining basic types with suitable system components, you receive complete compressor units and systems from a single source.